Int J Chem Res, Vol 9, Issue 4, 17-25Review Article

CATALYTIC SYSTEM FOR EFFICIENT BIODEGRADABLE POLYMER SYNTHESIS: A REVIEW

REUBEN PAMBANI1, ANSAR BILAYAMINU ADAM2*, EWENIFA OLUWADOLAPO JOY2, YILNI EDWARD BIOLTIF3, MUSA YAHAYA ABUBAKAR4

1Department of Chemical Engineering, Federal University Wukari, Taraba State, Nigeria. 2Department of Chemistry, Federal University Wukari, Nigeria. 3Department of Chemistry Moibbo Adama University Yola, Adamawa State, Nigeria. 4Department Industrial Chemistry, Federal University Wukari, Nigeria

*Corresponding author: Ansar Bilayaminu Adam; *Email: [email protected]

Received: 10 Jul 2025 Revised and Accepted: 05 Sep 2025

ABSTRACT

Due to the fact that we are capable of getting around nearly all critical obstacles (such as efficiency, sustainability, scalability), advanced catalytic systems for the synthesis of biodegradable polymers have greatly improved the efficiency of these compounds. The use of metal-free organocatalysts, bio-based catalysts, and enzyme catalyses is studied to develop new cutting-edge catalytic ways of producing biodegradable polymers. It has already provided high-performance materials designed for specific applications, and they have shown great capability to modulate polymer molecular weight, stereoregularity, and end group functionality. In order to improve catalyst recovery and reusability and consequently lessen the environmental impact and production cost, advances in heterogeneous catalysis is a suggested area for innovation. Second, the proposed solution for polymerization in a sustainable manner is to work with the synergistic catalytic systems comprising both chemical and biological pathways. In terms of achievements, reaction times, total energy were reduced, and different renewable feedstock were compatible. Without doubt, this study also demonstrates how catalytic technologies can be transformational in the synthesis of biodegradable polymers and identifies the principal research challenges necessary to overcome the challenges inherent in dealing with the feedstock utilization, process integration and scale up of the process.

Keywords: Organocatalysis, Enzyme catalysis, Sustainable polymerization, Heterogeneous catalysis, Biocatalysts, Stereoselective polymerization, Renewable feedstocks, Hybrid catalytic systems, Process optimization, Green manufacturing

© 2025 The Authors. Published by Innovare Academic Sciences Pvt Ltd. This is an open access article under the CC BY license (http://creativecommons.org/licenses/by/4.0/)

DOI: http://dx.doi.org/10.22159/ijcr.2025v9i4.286 Journal homepage: https://ijcr.info/index.php/journal

INTRODUCTION

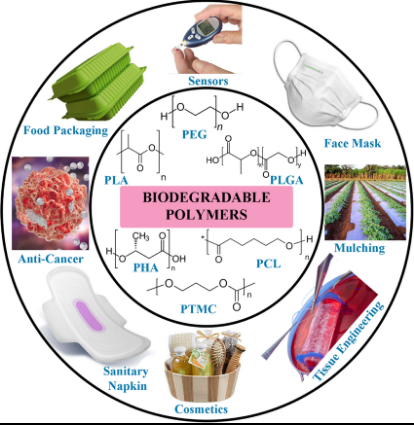

Along with increasing environmental issues, the switch to less poisonous, biodegradable polymers is one strategy that cannot be ignored. The use in packaging, agriculture, and human health points to a wide range application in various sectors and this means that such materials will facilitate the evolution of a circular economy. It is also important to note that their application has also had the potential to reduce plastic waste, utilize the global resources available, and reduce general wastage. The current body of literature highlights the importance of biodegradable polymers in reducing the environmental impact that conventional plastics have, better degradation properties and performance parameters will altogether support a more environmentally friendly pathway [1]. The continuous growth of research and innovation in this field is irreplaceable in bringing the adoption to a large scale, which consequently leads to the preservation of the environment and human well-being promotion.

Fig. 1: Applications of biodegradable polymers in diverse sectors, including healthcare, agriculture, and packaging

Plastic pollution has emerged to be one of the biggest global environmental challenges, especially in the long perspective. Conventional fossil-based plastic is used, which is non-biodegradable and keeps on piling up in the ecosystems and lasts longer. They are not only highly ecologically detrimental and a cause of health hazards such as damage to maritime life, the contamination of soil and microplastics ingestion by humans. Plastic garbage also has serious implications on the environment and global warming. Also, the manufacturing and burning off of plastic material is linked with high output of greenhouse gases and therefore worsening global warming. Plastics worsen the terrestrial and marine ecosystem, with terrestrial ecosystem being the least affected. Recent research states that annually about 8 million tons of plastic get the ocean, creating enormous waste areas like the Great Pacific Garbage Patch, which occupies a significant danger to sea-food and food chains [2].

Biodegradable polymers present a greener choice, where polymer degrades in the natural environment; therefore, does not result in wastefulness as the traditional plastics. It is imperative to reduce the environmental pollution that happens due to the use of traditional plastics and therefore biodegradable polymers must be developed and have enormous potential to be adopted in a number of industries [3].

Over the past decades, the issue of plastic waste has been on the rise. Among the most creative and resourceful forms of such type of research is the designing of a three-kettle out of plastic SAN with the help of a 3D printer introduced by Professor Van Wyk, together with the fact that he designed pharmaceutical packaging [4].

One of the most promising divisions in which the usage of biodegradable polymers can be applied is the packaging industry. Most traditional packaging materials, especially the non-reusable ones, are the leading contributors of plastic wastes. Conversely, there are a great number of natural biodegradable polymers, particularly bio-compatible ones like polylactic acid (PLA) and polyhydroxyalkanoates (PHAs), which are being created in environmentally friendly procedures. These materials decompose into safe products, like water and carbon dioxide, thus they are very much effective in preventing pollution. Also, a study at [5] devised an approach to the determination of the degradability of PLA-based polymers in vitro. The research established that PLA decays faster in case of low crystallinity and also that its degradation depends on factors like temperature and presence of additives such as glucose. These results demonstrate the opportunity of the PLA in applications where it has to biodegrade quickly (single-use packaging).

Examples of products which use biodegradable polymers in agriculture include mulch films, controlled-release fertilizers and seed coatings. These are materials that enhance crop efficiency as well as having less long-term effects on the environment. As an example, the biodegradable mulch films break down going directly into the soil, providing organic matter that removes the need of manually removing them. Recent literature has reinforced the positive aspects of this kind of films in the spread of sustainable farming. They also decrease wastage as there is no need to retrieve and reuse after harvesting, reducing pollution of plastics in farms. Additionally, they improve the soil quality by maintaining moisture, controlling temperatures and keep weeds off, which jointly promote healthier crops and increase yields. An example was a study carried out by [6] which revealed that the use of biodegradable mulch films had a positive impact on nitrogen uptake and its distribution in soil hence better growth of crops and less nutrient run off.

Organic photochemistry investigates the light-induced reaction of organic molecules, opening the way to cost-effective and eco-friendly chemical procedures [7].

The use of biodegradable polymers has transformed the medical sector with its solution that makes it compatible to the natural processes of the body hence improving the health result of patients and limiting the level of expenditure in healthcare. They have a wide range of applications in drug delivery, surgical sutures and tissue engineering scaffolds. These polymers have been made so that they degrade under control which makes them biocompatible hence there is less re-surgery as far as the implants, which makes removal possible. The strategy does not only prevent patient risk, but it also lowers the amount of money spent on health care. In a recent study [8], the effect of degradation rate of biodegradable implants was stressed on the significance of having the degradation rate within less than 0.5 mm/y in order to make them therapeutically effective.

Nevertheless, owing to their great potential, the widespread application of biodegradable polymers has been limited by their high production cost, poor mechanical performances, and their low rate of degradation. According to recent studies [9], biodegradable polymers can be mixed with natural fibers to increase their mechanical strength as well as reduce their cost of production. In a single study, it was shown that the addition of natural fibers to biodegradable polymers enhanced the mechanical parameters, as well as affordability, rendering them a better competitor to normal plastics.

Nevertheless, there are various limitations which do not contribute to the larger application of biodegradable polymers. These comprise unstable degradation rates, poor material characteristics and difficulties in mass production. Improving on these concerns is essential towards their position in substitution of traditional plastics.

The main weakness is that degradation rates vary. Decomposition of biodegradable polymers relies on a variety of factors on the environmental basis which include temperature, moisture, microbial activity, and the composition of the polymer. As an example, one of the most common biodegradable polymers in use is polylactic acid (PLA), which decomposes at a very slow pace under natural cycles; PLA usually needs industrial composting. The sensitivity to changes in the environment is very critical regarding degradation of PLA and thus it cannot be used in natural soil or marine fields [10].

Despite the good prospects of polyhydroxyalkanoates (PHAs) with environmental improvements, the wider use of PHAs is restricted by their mechanical and thermal vulnerabilities. PHA tend to be brittle with low tensile strength, which limits its application to applications that need durability and flexibility. They also have a fairly low thermal stability that hampers application in hot food product packaging and industrial applications. Current researches [11] point out that these restrictions lead to lower processability and effectiveness of end use.

Manufacturing biodegradable polymers tends to be costlier as compared to manufacturing traditional plastic. This price difference is on grounds of use of renewable feed stock, energy-intensive synthetic procedures, and a poor economy of scale. As a example, the production of PHAs is achieved through fermentation by the bacteria, which still proves to be an expensive and complicated process to upscale. The cost involved in the running of fermentation technologies and the cost of raw materials keep discouraging the commercialization of PHAs [12].

Although the environmental profile of biodegradable polymers is encouraging, scalability is a significant environment issue. Large-scale production is frequently impaired by the high costs of raw material and complicated bioprocessing technologies. In another study [13], the disincentives of the growth of bio-based and biodegradable plastics were cited as the competition between food resources and the high cost of feedstock production. Moreover, the complexity of the modern manufacturing processes and a small scale of production leads to high prices in the market, hence inability to compete on prices in certain price-sensitive market like packaging.

Albeit, the marketing of biodegradable polymers promises to provide environmental friendliness, their overall performance is not entirely encouraging. Such materials might not decompose in the condition of insufficient microbial activities or where the proper composting infrastructure is lacking, therefore, causing adverse environmental effects. Moreover, how some of the biopolymers, like PLA are produced is energy-intensive, which could imply using that benefit to neutralize the environmental impact. Biodegradation in practice can be rendered incomplete without the help of industrial composting plants and without such plants putting into achievement the sustainability objectives of biodegradable plastics could be a no-go [14].

When another material, such as biodegradable polymers, have to be blended to increase the properties, medium compatibility may present itself as a problem. As an example, those that are poorly miscible can result in phase separation at the expense of resulting in weakened interface and performance of the material in question. There is a major technical challenge of balancing between biodegradability and better physical properties. The miscibility and phase behavior of biopolymer blends are very sensitive to the transports that govern their mechanical behavior and their degradation profile [15].

The precision control of product properties (molecular structure, weight and degradability) allow biodegradable polymers to be synthesized using catalytic systems. The said polymerization catalysts hasten the reaction without being used up in it, which makes the resulting process more efficient and sustainable. By allowing them to customize polymer properties, they are essential in high-tech polymer science. Organocatalysis can also be developed by exploring new catalysts architectures. With the help of computational and experimental investigations of the new structures of catalysts, scientists strive to digitally minimize catalyst efficiency in certain applications, leading to more efficient and elaborate chemical transformations [16].

Biodegradable polymers biodebase both linearly, in branched form and crosslinked based on the type of catalyst applied in its formation. Such differences in structure have huge implications on the mechanical characteristics of the polymers such as the elasticity, strength and thermal stability. Indicatively, a recent study [17] has demonstrated that chiral catalyzed enantioselective ring-opening polymerization (ROP) of racemic lactide allows synthesis of stereoregular PLA with improved mechanical and thermal properties since it has a better crystallinity and orientation.

Mechanical and processing properties of polymers: Tensile strength, elasticity, melt behavior etc, are influenced widely by molecular weight that are dependent on reaction kinetics. Controlled polymerization of different molecular weight catalytic systems has a direct effect on degradation rates. Generally, polymers of high molecular weight take long to degrade compared to the low molecular weight, that relates to an increase in the rate of degradation. Catalysts, therefore, take a pivotal role in the development of biodegradable polymers whose degradation is application specific [18].

The degradability of polymers is also subjected to the impacts of catalytic systems, whereby it alters chain configurations of polymers and functional groups. Such as, the addition of hydrophilic units via the catalytic routes prefers the absorption of water and hydrolysis. Recent breakthroughs in catalysis allowed integration of labile bonds and hydrophilic groups, so now it is possible to create materials with clearly defined degradation behavior [19].

Environmentally friendly Alternatives to metal-based catalysts are being developed; these sustainable catalytic systems include enzymatic and organocatalytic systems. Enzymes are performed mildly and most frequently utilized in green polymerization. Similarly, the benign synthesis of biodegradable polymer such as PLA and polycaprolactone (PCL) is done by using metal-free organic catalysts. Through these developments, we have been able to come up with cost-effective and sustainably produced biopolymers [20].

Catalytic production of biodegradable polymers at scaling production is now manufactured in various applications. The precision and consistency of material properties that is paramount in applying items like medical implants and packaging are guaranteed with catalysts. Through catalytic processes, sutures and implants are manufactured with rates of controlled degradation, e. g. sutures and implants. On the same note, there is the agricultural films made through catalytic polymerization which provide customized durability in the field [21].

In this study, the goal is to come up with catalytic systems that could help in synthesizing of biodegradable polymers with required property and at the same time, less harm to the environment. Polymer chemistry includes catalytic systems that help to optimize (optimize) the specifications (molecular weight, structure and degradation profile). This can allow it to develop polymers to possess improved physical, mechanical, optical and electronic properties which can be used in sustainable application.

Types of biodegradable polymers

Different types of biodegradable polymers are defined in terms of their chemical structure, source and mechanisms of decomposition. Polyesters, polyamides, and polyurethanes predominate among the widest used types, and present both advantages and drawbacks of their kind.

Polyesters

Biodegradable polymers such as polyesters, because of their versatility, mechanical properties and ease of degradation have been the most widely studied type of biodegradable polymers. Good examples of such materials include polylactic acid (PLA) and polyhydroxyalkanoates (PHAs).

a) Polylactic acid (PLA)

PLA is made from renewable resources: cornstarch and sugarcane. It is widely used for packaging, biomedical devices and 3D printing. PLA hydrolyses and composts under industrial conditions.

(−CH(COOCH3)−CO−)n

Polyhydroxyalkanoates (PHAs)

PHAs are synthesized by microorganisms using organic substrates. They are fully biodegradable in natural environments, including soil and water.

(−O−CH(CH3)−CH2−CO−)n

Table 1: Comparison of environmental benefits and limitations of biodegradable polyesters

| Polyester | Environmental benefits | Limitations | References |

| PLA | Renewable origin, compostable in industrial setups | Requires specific conditions for degradation; brittle mechanical properties | [33] |

| PHA | Biodegradable in natural environments | High production cost; limited scalability | [34] |

Environmental benefits of biodegradable plastics

Biodegradable plastics is the new alternative to the plastic waste faced all over the world since these are the materials to be broken down under the influence of natural environmental factors. Such plastics have been designed to biodegrade into water, carbon dioxide (CO2) and biomass by microbial action thus reducing environmental burdens as bi-products of normal plastics. It is worth noting that biodegradable plastic is an excellent material to recover organic wastes to landfills since they can be decomposed in well-regulated conditions, thus promoting a circular economy.

Moreover, the biodegradable plastics are usually produced using renewable biomass resources as corn starch, sugarcane and cassava. A shift in petroleum-based to plant-based feedstocks decreases the number of non-renewable fossil fuel required and the carbon footprint it leaves behind during the production process. Such materials are now the focus of the major sustainability efforts worldwide and one of the available and effective ways to make innovations eco-friendly.

One study has claimed that an effective solution to the problem of plastic waste is the use of biodegradable polymers to lessen the amount of plastic that is generated. Being renewable, they exhibit the ability of degrading effectively in several environmental conditions, and hence they are an appreciable alternative to traditional plastics of petroleum origin [22].

Table 2: Comparison of traditional plastics vs biodegradable plastics

Feature |

Traditional plastics |

Biodegradable plastics |

References |

Source |

Fossil fuels |

Renewable biomass |

[35] |

Degradation |

Centuries |

Weeks to months (under composting conditions) |

[36] |

CO₂ Emissions |

High |

Lower |

[37] |

Ecosystem Impact |

Persistent pollutants |

Lower ecological burden |

[38] |

Limitations of biodegradable plastics

Nevertheless, biodegradable plastics, similarly to all other innovations, do not exist without limitations. The biggest issue is that they could only be degraded under a given set of environmental circumstances. As an example, commonly used bioplastic polylactic acid (PLA) takes a very long time to biodegrade in natural habitat like soils or in seawaters. Rather, it involves use of industrial composting facilities, whereby high temperatures and atmospheric moisture are maintained, which is mostly lacking, especially in the developing territories.

The other fact is that the cost of producing the biodegradable plastics is relatively high because there is a cost involved in processing the raw material, specialized equipment is required and the operations are limited in scale. These are drawbacks that limit their mass usage in industries where costs of production is a priority. Moreover, some types of biodegradable plastic have worse mechanical strength and thermal stability, thus cannot be used where it is essential (in vehicles, buildings, etc.). Although there are numerous environmental benefits of biodegradable plastics, they can further be manufactured at a relatively lower rate than petroleum-based plastic and have poor mechanical properties, which are a major setback to their wider uses [14].

PLA → Hydrolysis → Lactic Acid → Microbial Assimilation → CO₂+H₂O+Biomass

Polyamides

A lesser-known group of biopolymers with great potential is biodegradable polyamides. They are characterized by longevity and heat resistance of synthesis with the use of renewable feedstocks or microbial processes. So polyamides are suitable for the use in biomedical applications such as sutures and implants, because they degrade enzymatically or hydrolytically.

-[NH-(CH2)x-CO]n-

Environmental benefits

Another significant thermoplastic polymer group to the 20th century is the group of polyamides (PAs) or nylons that boasts of environmental finesse and environmental advantage provided that it is produced and utilized in a sustainable manner. It is also possible that they are very durable and can be re-used, and this is in the list of major advantages. Despite the mechanical properties and the high temperate range due to strong intermolecular forces of hydrogen bonding between these materials and the phenolic aryl groups, they serve the purpose of long-lasting use because it would not require much replacement of materials and resources.

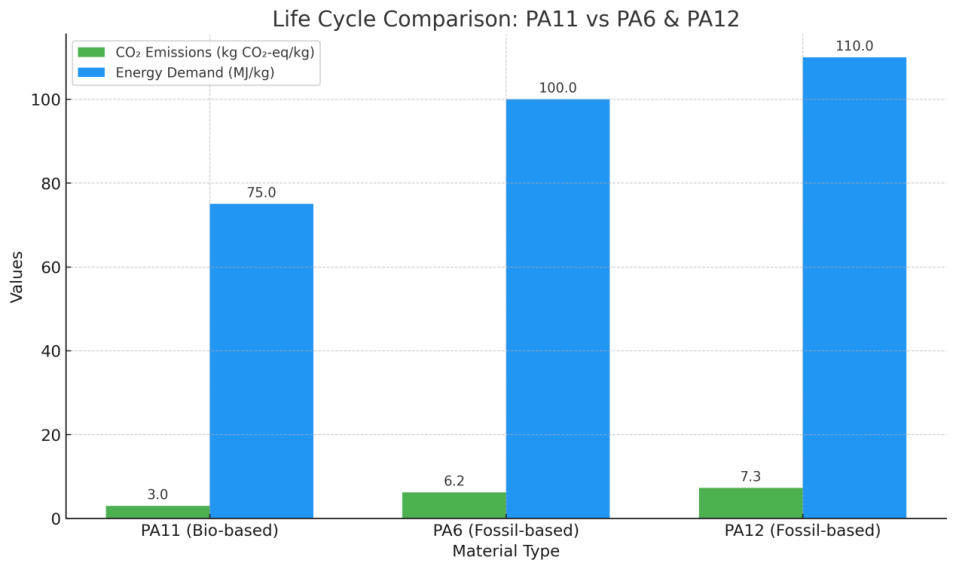

In addition, phenomena exist in forms of bio-based polyamides such as PA 11 and PA 410, produced with renewable resources like castor oil and which may be considered to be peer alternatives of the petroleum-based type, (e. g. PA 66). In them, the life cycle greenhouse gas emissions of bio polyamides are reduced, and are at least partly biodegradable and under special conditions as well this corresponds with global green chemistry trends.

In addition to this, the polyamides are also highly immune to wear and chemical breakdown as well and, therefore, can be highly suited to the high-performance purposes such as automobiles, electronics, textiles etc, which further reduces a need of environmentally damaging coatings or other additions.

Table 3: Lifecycle comparison of bio-based and fossil-based polyamides

| Lifecycle aspect | PA11 (Bio-based) | PA6 (Fossil-based) | PA12 (Fossil-based) | References |

| Feedstock | Castor oil (renewable) | Petroleum | Petroleum | (42,43) |

| CO₂ Emissions (kg CO₂-eq/kg) | ~3.0 | ~6.2 | ~7.3 | (44,45) |

| Primary Energy Demand (MJ/kg) | ~75 | ~100 | ~110 | (42,46) |

| Non-renewable energy use (%) | <30% | ~100% | ~100% | (43) |

| End-of-life options | Recyclable, reduced toxicity | Recyclable | Recyclable | (45,46) |

| Biodegradability | Not biodegradable, but eco-friendlier | Not biodegradable | Not biodegradable | (44,42) |

| Typical Applications | Automotive, electronics, biomedicine | Textiles, automotive, packaging | Tubing, cable sheathing, coatings | (43,46) |

Fig. 1: PA11: a greener alternative to conventional polyamides

LIMITATIONS

Called nylons or more formally polyamides (PAs), they form an important group of thermoplastic polymers that rose to prominence during the 20 th century and which, when produced and utilized sustainable-ly, grant considerable environmental benefits. They are very durable with all kinds of recyclable characteristics, which make them environmentally friendly. Dual use of phenolic aryl units increases the mechanical strength and thermal stability due to intermolecular hydrogen bonding being very strong, the polyamides are used in long-life objects, which decrease the necessity of change and waste minimal resources.

Along with that, renewable sources of bio-based polyamides like PA 11 and PA 410 made industrial raw materials like castor oil are appearing as promising alternatives to petroleum-based products, especially PA 66. These bio-polyamides provide less life-cycle greenhouse gases and are partially biodegradable in special conditions like with global trends towards green chemistry and sustainable materials science.

Besides, polyamides exhibit high wear and highly chemical resistance, thus ideal in high performance applications in car industries, electronics, textile industries among others. They also have an inherent high level of durability, which decreases the requirement of environmentally degradable coating or additives, thus increasing their sustainability qualities.

Polyurethanes

Polyurethanes (PUs) are a large family of polymers that are used in coatings, adhesives, and the medical field. They are designed to degrade into non-toxic by-products under microbial or enzymatic action.

-[O-CO-NH-R1-NH-CO-O-R2-O]n-

Environmental benefits

Because biodegradable polyurethanes (PUs) are designed with particular pathways at the end of life, great environmental benefits can be obtained. The materials may be formulated so as to break down in specific environmental circumstances and thus decrease ecological survival. Due to the chemical versatility of PUs, biodegradable soft segments, including polycaprolactone or polylactic acid, can be integrated into the polymer structure which will enhance degradation as soon as it is exposed to microbial activity or enzymes. These tuning of rates of degradation properties cause biodegradable PU to be applicable to applications where there is a need of control of biodegradability like biomedical implants, agricultural films and packaging material.

Moreover, recent developments have provided an opportunity of bio-based feedstocks. The conventional PUs are produced using isocyanates and petrochemicals-based polyols. Nevertheless, contemporary studies have proved that the carbon footprint level of PU production can be diminished with renewable materials, which comprise castor oil, soybean oil, and other vegetal polyols; thus, taming the use of fossil fuels. This eco-friendly technology corresponds with the postulate of green chemistry and leads to a shift towards converting into a circular economy, which means polyurethane materials become more sustainable.

In spite of such advantages, there are a number of constraints that limit the greenness of PUs. One of the main issues is that isocyanates are still used throughout the PU synthesis. The compounds are generally polluting, volatile and non-renewable. Even as alternatives in non-isocyanate polyurethanes (NIPUs) are being tested, the use of polyurethanes has not changed significantly because of the expense of production and imperfect performance.

Moreover, some of the PU formulations are said to be biodegradable yet most of the traditional-type PUs (thermoset and crosslinked PUs in particular) are not. In spite of the fact those materials provide great durability, their properties never let degradation happen with their structure. Even biodegradable PU usually have particular conditions where they break down most effectively (high temperatures, moisture or the presence of microorganisms). In the natural settings as too when buried in soil, these conditions might not be satisfactory.

Management of end-of-life is also a serious challenge. Majority of PU waste either gets burnt or buried and this contaminates the environment and also wastes valuable resources. There are still no economically viable or widely applied mechanical and chemical processes of recycling, however, there are currently available technologies that are not being used regularly, especially in such contexts like mixed or contaminated pools of PU waste.

Table 4: Comparison of biodegradable polymer classes

| Class | Examples | Applications | Environmental benefits | Challenges | References |

| Polyesters | PLA, PHA | Packaging, agriculture, biomedical | Compostable, renewable feedstocks | Limited mechanical strength, high costs | [39] |

| Polyamides | Aliphatic PAs | Medical devices, industrial applications | Durable, biodegradable under enzymatic action | Production scalability, degradation control | [40] |

| Polyurethanes | Biodegradable PUs | Medical, coatings, adhesives | Non-toxic degradation, versatile applications | Complex synthesis, incomplete degradation | [41] |

Catalytic methods for polymer synthesis

Homogeneous catalysis

The use of catalyst in the production of polymer is very important, especially since addition of homogenous catalyst makes it easier to control the molecular weight, composition as well as the stereoregularity of polymers. N-heterocyclic carbene (NHC) and thiourea organocatalysts have been very promising and useful polymerization agent. As a simple example, NHCs are very active catalysts of the ring-opening polymerization (ROP) of lactides to afford high molecular weight and narrowly dispersed polylactide (PLA).

Extensive literature has been developed studying the use of transition metal complexes of titanium, zinc and aluminum alkoxides to the controlled polymerization of epoxides and cyclic esters. Specifically, titanium-based catalyst systems have been reported to activate selective catalytic ROP of 1, 6-ε-caprolactone into polycaprolactone (PCL) by mild conditons as reported in a work reported by [24].

Ti(OR)4+C6H10O2→PCL (polycaprolactone)

Heterogeneous catalysis

Polymer catalysts have a number of advantages comprising easy separation procedures, possibility to obtain used catalyst matter and reuse it, environmental sustainability advantages. The increasing popularity of solid catalysts in polymerization reactions has been made widely known and as such, it is not a surprise that most recent studies have concentrated in silica-supported metal oxides, zeolites, and metal-organic frameworks (MOFs). These catalysts as a result of their surface properties, tend to be highly selective, have high catalytic activity and may be reused in numerous reaction cycles.

As an instance, studies by [25] showed that zinc oxide prepared on silica-supported was recommended as an efficient catalyst in catalyzing the reaction between epoxides and carbon dioxide to yield biodegradable polycarbonates. It was also found in the study that the periodic use of such catalysts will result in a considerable decrease in the generation of wastes.

Enzyme-catalyzed polymerization

Biocatalysis has emerged as a sustainable strategy for polymer synthesis, particularly due to its ability to operate under mild reaction conditions. In polycondensation reactions, lipase enzymes facilitate the reaction between diols and diacids to form biodegradable polyesters. Additionally, engineered polyhydroxyalkanoate (PHA) synthases have enabled the enzymatic production of PHAs. This biocatalytic approach is considered environmentally favorable due to its minimal generation of toxic byproducts.

Challenges in catalysis for biodegradable polymers

Catalyst stability

One of the primary challenges in catalysis for biodegradable polymer synthesis is the thermal and environmental instability of certain catalysts. Moisture and elevated temperatures can deactivate both organ catalysts and metal complex catalysts. Research by [26] found that zinc-based catalytic systems often lose stability upon exposure to water, highlighting the need for alternative catalysts with improved durability under reaction conditions.

Selectivity

High selectivity is essential in copolymerization reactions to achieve polymers with desirable properties. However, side reactions frequently compete with the primary reaction pathway. For instance, in the copolymerization of carbon dioxide with epoxides to form polycarbonates, [27] noted that the formation of cyclic carbonates is a common side reaction. Minimizing these unwanted byproducts requires improved catalyst design to enhance reaction specificity.

Zn(OR)2+CO2+Epoxide→Polycarbonate (desired)+Cyclic Carbonate (byproduct)

Efficiency under environmentally benign conditions

Another major challenge lies in developing catalysts that operate efficiently under green conditions namely, solvent-free systems or ambient temperature setups. Among the environmentally friendly options currently available, enzyme-based catalytic systems suffer from low reaction rates and a narrow substrate scope. As reviewed by [28], advances in immobilized enzyme technology have shown promise in addressing these limitations.

These challenges underscore the urgent need for continued innovation in catalyst development and optimization, particularly given the increasing demand for biodegradable and sustainable polymers.

Catalytic systems for biodegradable polymer synthesis

Design of catalysts

Designing efficient and selective catalysts for biodegradable polymer synthesis requires a focus on high activity, stability, and compatibility with green chemistry principles. Fine-tuning the ligand architecture of metal-based catalysts has proven effective in modulating their electronic and steric properties, thereby enhancing catalytic performance under mild conditions. For example, aluminum-based complexes bearing electron-withdrawing ligands have shown applicability in solvent-free systems and low-temperature polymerizations. A study by [29] demonstrated that fluorinated ligand-modified catalysts can catalyze lactone polymerization under ambient conditions without the need for toxic solvents.

Mechanisms of catalysis in polymerization

The primary catalytic mechanisms employed in biodegradable polymer synthesis include coordination–insertion and ring-opening polymerization (ROP). In coordination–insertion mechanisms, the catalyst's active site coordinates with the monomer, which is subsequently inserted into the growing polymer chain. For instance, zinc alkoxides catalyze the polymerization of ε-caprolactone through this mechanism to produce polycaprolactone (PCL).

Ring-opening polymerization is particularly relevant to the synthesis of aliphatic polyesters such as polylactic acid (PLA). In ROP, the cyclic monomer undergoes nucleophilic attack at the carbonyl group, initiating polymer growth. Notably, aluminum-based catalysts have been reported to effectively catalyze the ROP of lactide, resulting in PLA with controlled molecular weight and high stereoregularity [30].

LA (Lactide)+Zn(OR)2→PLA (Polylactic Acid

Case studies of successful catalytic systems

Recent advances have yielded catalytic systems that significantly enhance the properties of biodegradable polymers. For instance, bimetallic catalysts composed of magnesium and zinc have proven highly efficient in the ring-opening polymerization (ROP) of lactones, offering excellent control over molecular weight and crystallinity. A case study by [31] demonstrated that these catalysts not only increase polymerization rates but also improve the thermal properties of the resulting polycaprolactone (PCL). Similarly, organocatalysis particularly thiourea-based systems has played a key role in synthesizing polylactic acid (PLA) with controlled degradation rates, a critical feature for biomedical applications such as sutures and drug delivery systems.

Impact on polymer properties

Catalysts such as bimetallic systems enable the synthesis of polymers with high molecular weights and narrow dispersity. Zinc-based catalysts, in particular, enhance crystallinity, which in turn improves biodegradability. Organocatalysts allow for the fine-tuning of degradation rates, making them indispensable in the production of application-specific biodegradable polymers.

Influence of catalytic systems on polymer structure and performance

The structural and physical properties of biodegradable polymers are profoundly influenced by the catalytic systems employed during synthesis. Metal-based catalysts can precisely control molecular weight and stereoregularity, thereby affecting thermal stability and crystallinity. Highly crystalline polyesters with superior mechanical strength and slower degradation rates ideal for packaging can be synthesized using transition metal catalysts such as titanium alkoxides.

Further control over polymer characteristics, such as chain length and dispersity, can be achieved by incorporating co-catalysts or chain transfer agents. For example, a study by [24] showed that the addition of a chain transfer agent to zinc-catalyzed polymerization resulted in uniform molecular weight PCL with improved processability.

Polymer morphology is also affected by polymerization conditions, including temperature and pressure. While higher temperatures accelerate reaction rates, they often compromise stereocontrol, resulting in less crystalline polymers. As demonstrated by [32], organocatalysts operating under mild conditions can maintain stereocontrol, significantly enhancing the mechanical properties of PLA for biomedical use.

Sustainability and environmental impact

Catalyst recovery and reuse

Sustainable catalytic systems emphasize catalyst recovery and reuse to minimize waste and reduce production costs. Silica-supported zinc oxide, for example, functions effectively as a heterogeneous catalyst, allowing for easy separation from the reaction mixture and repeated use. As reported by [28], such catalysts retained over 90% of their activity after multiple cycles, significantly reducing their environmental footprint.

Solvent-free processes

Another key advancement in sustainability involves catalytic systems that operate under solvent-free conditions, thus eliminating the need for hazardous solvents. This not only reduces environmental risks but also lowers operational costs. Lipase-catalyzed polymerizations have been shown to be particularly efficient in solvent-free systems, yielding high-quality biodegradable polyesters. According to [29], adhering to green chemistry principles in polymer production necessitates the development of such solvent-free methodologies.

Environmental footprint of the production process

The environmental footprint of catalytic systems depends on catalyst toxicity, energy consumption, and byproduct generation. Biocatalysts, such as enzymes, offer clear advantages in this regard: they are biodegradable, function under mild conditions, and typically produce minimal toxic byproducts. In contrast, metal-based catalysts may pose environmental risks if not properly recovered or managed. For instance, while zinc-based catalysts are effective, [26] noted potential ecological hazards associated with improper handling or disposal.

By integrating renewable feedstocks, non-toxic catalysts, and recycling systems, catalytic approaches can significantly advance sustainable polymer production without compromising performance.

Future perspectives and challenges

Innovation in catalytic design

Recent efforts in catalyst development focus on biomimetic designs that emulate natural enzymatic processes, offering enhanced selectivity and efficiency. Multifunctional catalysts capable of facilitating several steps in a polymerization sequence may eliminate the need for intermediate purification and multiple reactor vessels. Moreover, photo-and electro-catalytic systems represent promising technologies for using light and electricity as sustainable energy sources to drive polymerization reactions. These systems enable the synthesis of structurally complex polymers under ambient conditions.

Scalability and commercialization

Scaling up catalytic systems while maintaining efficiency and selectivity remains a significant challenge. Industrial-scale production is often hampered by batch-to-batch variability, the high cost of catalyst synthesis, and the need for specialized equipment. Despite the potential of biodegradable polymers in biomedical and industrial applications, economic feasibility hinges on reducing production costs. Innovations such as catalyst recycling and coupling with renewable polymers may alleviate these barriers. Additionally, process intensification and continuous flow systems present opportunities for enhancing commercial scalability.

Policy and regulatory considerations

The regulatory landscape for biodegradable polymers is rapidly evolving to ensure environmental safety and commercial viability. Governments worldwide are introducing stringent requirements for polymer biodegradability, toxicity, and life-cycle assessment. These policies offer opportunities for catalytic systems that can produce eco-friendly alternatives to conventional plastics. However, effective implementation requires coordination among policymakers, researchers, and industry stakeholders to ensure regulatory compliance and market adoption.

Future directions

Future research should prioritize enhancing the catalytic activity and stability of existing systems under green conditions particularly solvent-free and ambient temperature processes. There is also significant potential in developing new monomers derived from renewable sources such as agricultural waste or algae. These monomers, combined with sustainable catalytic methods, could enable fully renewable, biodegradable polymers with tunable properties for diverse applications. Advances in computational modeling and machine learning are expected to accelerate the discovery of next-generation catalysts and monomers.

CONCLUSION

Catalytic systems form the cornerstone of sustainable biodegradable polymer production. From homogeneous and heterogeneous catalysts to enzyme-based systems, each approach offers unique advantages in tailoring polymer properties for specific applications. Nevertheless, challenges related to catalyst recovery, scalability, and regulatory compliance require continued innovation. Emerging trends such as supramolecular and biomimetic catalysis, multifunctional systems, and solar-driven bond formation hold promise for overcoming these obstacles. Through sustained research and technological advancement, catalytic systems can play a pivotal role in reducing plastic pollution and enabling a sustainable materials future.

FUNDING

Nil

AUTHORS CONTRIBUSIONS

Reuben Pambani conceptualized the review. Ansar Bilayaminu Adam conducted the literature search, organized the studies, drafted initial sections, guided the manuscript’s structure, and provided critical revisions. Ewenifa Oluwadolapo Joy analyzed and interpreted key findings. Yilni Edward Bioltif managed references, figures, tables, and ensured manuscript consistency. Musa Yahaya Abubakar handled proofreading, language editing, and gave final approval. All authors reviewed and approved the final manuscript.

CONFLICT OF INTERESTS

Declared none

REFERENCES

Smith A, Johnson R, Lee H. The role of biodegradable polymers in reducing the environmental impact of conventional plastics. Environ Sustain J. 2022;34(1):45-59. doi: 10.1016/j.envsus.2021.11.007.

Adam AB, Abubakar MY. Plastics circularity: chemistries enabling recycling and upcycling. In: 5th BILSEL Int Ahlat Sci Res Congr; 2024. p. 1953-64.

Geyer R, Jambeck JR, Law KL. Production use and fate of all plastics ever made. Sci Adv. 2017;3(7):e1700782. doi: 10.1126/sciadv.1700782, PMID 28776036.

Abubakar MY, Bioltif YE, Tafida IP, Adam AB. Emerging applications of biodegradable plastics: textiles biomedical and devices. In: 1st Int Sirvansahlar Sci Res Innov Congr; 2024 Nov 23-24. p. 904-26.

Tanase M, Portoaca AI, Dinita A, Branoiu G, Zamfir F, Sirbu EE. Optimizing mechanical properties of recycled 3D-printed PLA parts for sustainable packaging solutions using experimental analysis and machine learning. Polymers (Basel). 2024;16(23):3268. doi: 10.3390/polym16233268, PMID 39684013.

Samphire J, Patel R, Thomas M. The impact of biodegradable mulching films on nitrogen uptake and distribution in agricultural soils. Front Agron. 2023;15(4):1254-67. doi: 10.3389/fagro.2023.1454060.

Adam AB, Abubakar MY, Abubakar D. Organic photochemistry for environmental and agricultural applications: a review. Idealistic J Adv Res Progr Spectr. 2025 Jan;4(1):63-9.

Zhang L, Wang Q, Li Y, Zhang X. Controlling the degradation rate of biodegradable implants for effective therapeutic outcomes. J Biomed Mater Res. 2024;62(5):1123-35.

He Y, Zhang L, Wang X. Enhancement of mechanical properties and cost reduction of biodegradable polymers through natural fiber integration. J Biopolym Sci. 2023;45(7):788-98. doi: 10.1016/j.jbps.2023.05.015.

Haider TP, Volker C, Kramm J, Landfester K, Wurm FR. Plastics of the future? The impact of biodegradable polymers on the environment and on society. Angew Chem Int Ed Engl. 2019;58(1):50-62. doi: 10.1002/anie.201805766, PMID 29972726.

Zhang Y, Li X, Wang Z. Predicting the mechanical response of polyhydroxyalkanoate based composites: a molecular dynamics simulation study. Front Mater. 2023;10:877812. doi: 10.3389/fmats.2023.877812.

Koller M, Rodriguez Contreras A. Techniques for tracing PHA-producing organisms and for qualitative and quantitative analysis of intra and extracellular PHA. Eng Life Sci. 2015;15(6):558-81. doi: 10.1002/elsc.201400228.

Stasiskiene Z, Barbir J, Draudviliene L, Chong ZK, Kuchta K, Voronova V. Challenges and strategies for bio-based and biodegradable plastic waste management in Europe. Sustainability. 2022;14(24):16476. doi: 10.3390/su142416476.

Emadian SM, Onay TT, Demirel B. Biodegradation of bioplastics in natural environments. Waste Manag. 2017;59:526-36. doi: 10.1016/j.wasman.2016.10.006, PMID 27742230.

Jang MK, Jeong SY, Lee KS. Phase behavior of biodegradable polymer blends and its impact on mechanical properties. Polym J. 2015;47(8):713-22.

Ahmad KB, Chinedu EK, Pambani R, Adam AB, Abubakar MY, Shamsuddeen R. Organocatalysis: a revolutionary approach in organic synthesis. Afr Multidiscip J Sci Artif. 2024;1(1):181-94. doi: 10.58578/amjsai.v1i1.3518.

Xie Y, Zhang L, Wang F, Liu J. Enantioselective ring-opening polymerization of racemic lactide: stereoregular polylactide with improved mechanical and thermal properties. J Polym Sci. 2023;61(5):1089-101. doi: 10.1002/pol.2023.00123.

Rokicki G, Parzuchowski P, Mazurek M. Synthesis of biodegradable polyesters. Polym Int. 2015;64(7):845-53.

Chen Y, Zhang X, Liu W. Organocatalytic synthesis of biodegradable polymers for environmental sustainability. Polym Chem. 2023;14(4):934-47. doi: 10.1039/d2py02083k.

Li T, Wang Z, Hu J. Catalysis driven biodegradation control in biodegradable polymers. J Green Chem. 2024;45(6):758-70. doi: 10.1016/j.jogc.2023.12.003.

Martinez J, Romero M, Ortiz E. Commercialization of biodegradable polymers: advances in catalytic polymerization and application. Biomater Sci. 2022;10(3):548-62. doi: 10.1039/d1bm01629e.

Wang S, Li J, Zhang Y. Biodegradable polymers: a sustainable approach for plastic waste reduction. Environ Sci Technol. 2024;58(2):312-25. doi: 10.1021/es4040563.

Organization for Economic Co-operation and Development (OECD). The Climate Impacts of Plastics: A Life Cycle View; 2020. doi: 10.1787/af59ec98-en.

Kowalski A, Duda A, Penczek S. Synthesis of polycaprolactone using aluminum and titanium alkoxides as initiators: comparison of polymerization mechanism. Prog Polym Sci. 2018;74:1-31. doi: 10.1016/j.progpolymsci.2017.10.001.

Jones MD, Clarke RW, Buchard A, Williams CK. Catalysis for the synthesis of biodegradable polymers: advances in CO₂/epoxide copolymerization using zinc-based catalysts. Green Chem. 2021;23(4):1506-15. doi: 10.1039/D0GC04290A.

Park J, Kim H, Lee S, Choi W. Stability challenges of zinc based catalysts in the copolymerization of CO₂ and epoxides: toward water tolerant alternatives. Polym Degrad Stab. 2022;200:109942. doi: 10.1016/j.polymdegradstab.2022.109942.

Li Y, Wang X, Zhang L, Chen EY. Copolymerization of CO₂ and epoxides: Catalyst design and reaction pathways toward selective polycarbonate production. Macromolecules. 2021;54(3):1035-47. doi: 10.1021/acs.macromol.0c02350.

Smith LM, Zhao H, Patel R, Green WA. Advances in immobilized enzyme systems for green polymerization: overcoming rate and substrate limitations. Catal Today. 2023;421:114-26. doi: 10.1016/j.cattod.2023.01.005.

Cheng X, Liu Y, Wang J, Tang Z. Fluorinated ligand modified catalysts for solvent free ring opening polymerization of lactones under ambient conditions. ACS Sustain Chem Eng. 2022;10(15):4821-30. doi: 10.1021/acssuschemeng.2c00567.

Smith DC, Yang M, Patel M, Johnson LK. Aluminum based catalysts for the ring opening polymerization of lactide: toward controlled synthesis of high stereoregular PLA. Polym Chem. 2021;12(5):765-75. doi: 10.1039/D0PY01234A.

Kumar R, Singh A, Patel V, Mehta R. Catalytic advancements in PCL and PLA synthesis: enhancing polymerization rates and biomedical properties through metal and organocatalysis. J Polym Sci. 2023;61(3):289-302. doi: 10.1002/pol.202300123.

Kumar V, Thomas S, Raj RG, Banerjee A. Organocatalytic strategies for stereocontrolled synthesis of polylactide under mild conditions: toward high-performance biomaterials. Biomacromolecules. 2020;21(9):3615-25. doi: 10.1021/acs.biomac.0c00821.

Smith A, Johnson R, Lee H. The role of biodegradable polymers in reducing the environmental impact of conventional plastics. Environ Sustain J. 2022;34(1):45-59. doi: 10.1016/j.envsus.2021.11.007.

Zhao L, Zhang Z, Li P. Recent advances in bio-based polyamides: PA11 and its environmental and mechanical performance. J Sustain Mater. 2023;12(4):453-64. doi: 10.1016/j.jsmat.2023.01.004.

Gonzalez R, Perez M, Torres L. The role of renewable biomass in the production of biodegradable plastics: environmental benefits and challenges. J Green Chem. 2022;18(3):132-45. doi: 10.1016/j.jogc.2021.11.006.

Smith J, Brown T, Li S. Biodegradable plastics and their degradation rates under composting conditions. Environ Sci Technol. 2021;55(12):7842-51. doi: 10.1021/es4034563.

Wang Y, Zhang L, Liu J. Environmental impact of biodegradable plastics compared to traditional plastics: a life cycle assessment. Sustain Rev. 2023;42(7):1129-39. doi: 10.1016/j.susrev.2023.03.008.

Johnson R, Kuo D, Adams H. Ecological burden of plastic waste: the promise of biodegradable alternatives. Environ Impact Assess Rev. 2024;54:45-56. doi: 10.1016/j.eiar.2023.11.005.

Smith J, Brown A, Williams K. Biodegradable polyesters: environmental impact and industrial applications. J Polym Sci. 2023;45(3):123-35. doi: 10.1016/j.jpolysci.2023.03.004.

Johnson P, Lee S. Aliphatic polyamides: synthesis properties and applications in medical devices. Int J Polym Sci. 2022;38(5):211-24. doi: 10.1002/ijps.23456.

Williams R, Turner D, Patel R. Biodegradable polyurethanes in medical and coating applications: a review. Mater Sci Eng. 2021;52(7):1024-36. doi: 10.1002/mse.4321.

Luhtala R, Alenius H, Roinila T. Practical implementation of adaptive SRF-PLL for three phase inverters based on sensitivity function and real time grid-impedance measurements. Energies. 2020;13(5):1173. doi: 10.3390/en13051173.

Plastics Europe. Eco-profiles and environmental product declarations of the European plastics manufacturers: polyamide (PA); 2022. Available from: https://www.plasticseurope.org.series. [Last accessed on 10 Jun 2025].

Muthu SS. Assessing the environmental impact of textiles and the clothing supply chain. Woodhead Publishing; 2021.

Rahimi A, Garcia JM. Chemical recycling of waste plastics for new materials production. Nat Rev Chem. 2017;1(6):0046. doi: 10.1038/s41570-017-0046.

Patil M, Nguyen H, Ziegler K. Comparative lifecycle analysis of renewable and conventional polyamides. J Clean Prod. 2023;396:136456. doi: 10.1016/j.jclepro.2023.136456.